WE LOVE WHAT WE DO

Production

Our Business is Cheese...

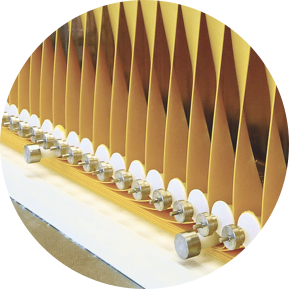

...and this is how it is made.

In order to make good cheese, it takes calmness, thouroughness, cheese know-how and years of experience. You want the abstract? Here we show you the different production steps in fast-forward: